Innovations in sheet metal cutting have become one of the key factors shaping competitiveness in the metalworking industry. With the rapid development of technology, innovations in sheet metal cutting are transforming production processes by increasing precision, efficiency, and automation.

In this article, we take a closer look at the modern sheet metal cutting technologies that have gained importance in recent years and explain why investing in CNC sheet metal cutting machines can provide a competitive advantage. We discuss the potential of fiber lasers, the advantages of CNC plasma cutting, and the impact of automation in sheet metal processing on the future of the industry.

The Evolution of Sheet Metal Cutting Technology

The process of cutting sheet metal has come a long way—from simple manual tools to today’s advanced CNC sheet metal cutting machines. Each step in this evolution aimed to increase precision, reduce production time, and lower manufacturing costs.

Traditional Cutting Methods

Just a decade ago, methods such as mechanical cutting (e.g., guillotine shears), oxy-fuel cutting, or manual plasma cutting dominated the market. Although effective, these methods were time-consuming, inflexible, and often required additional finishing operations.

Limitations of Older Technologies

-

Low cutting precision, especially with thin sheets

-

High material loss due to wide kerf

-

High operating costs (gas consumption, wear parts, energy use)

-

No possibility of quick parameter changes or automated programming

The Breakthrough – Digitization and Automation

The turning point was the introduction of CNC technology, which enabled programmable, repeatable, and highly accurate cutting. The next leap forward was integrating machines with CAD/CAM systems and, today, increasingly with cloud-based tools and data analytics.

Thanks to this, processes such as fiber laser cutting, CNC plasma cutting, or bending on CNC press brakes are now faster, more reliable, and easy to monitor in real time.

Fiber Laser – The Leader of Modern Cutting

The fiber laser is currently one of the most advanced technologies in sheet metal cutting. Its advantage lies not only in its exceptional precision but also in its efficiency and low operating costs.

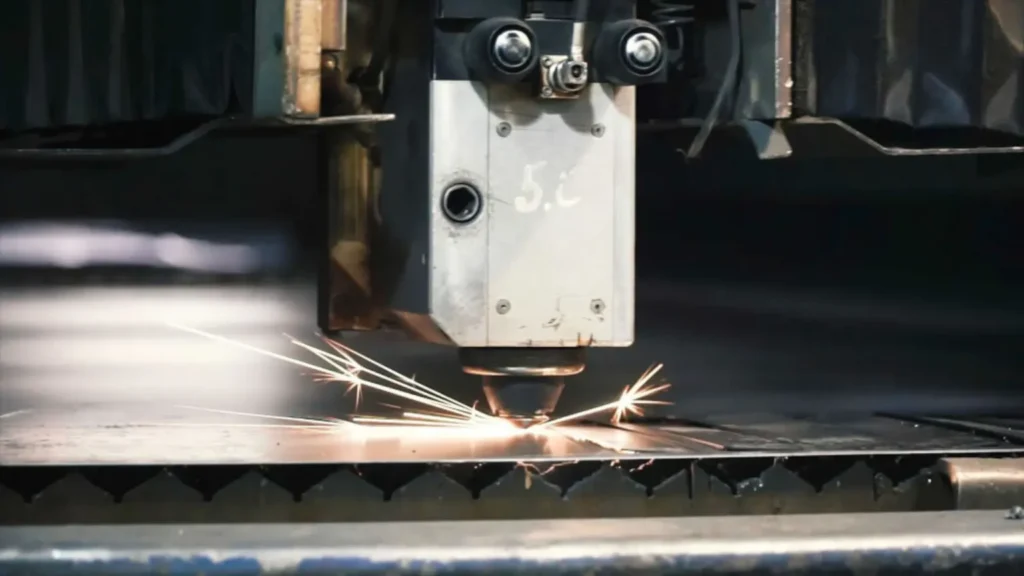

How Does a Fiber Laser Work?

Unlike traditional CO₂ lasers, a fiber laser uses light generated by laser diodes and transmitted through a special optical fiber. This makes the machine more compact, more stable, and more energy-efficient.

Applications in Industry

Fiber laser sheet metal cutting is widely used in the automotive industry, construction, metal furniture manufacturing, and machine component production. This technology is suitable for materials such as structural steel, stainless steel, aluminum, brass, and copper.

Key Advantages

-

Precise metal cutting—parts often require no additional finishing

-

High cutting speed—ideal for series production

-

Low operating costs—no laser gases required

-

Versatility—cutting thin and thick sheets on one machine

-

Low failure rate thanks to simple machine architecture

Why Invest in Fiber Laser Technology?

With increasing production costs and pressure for shorter delivery times, a fiber laser cutting machine is a strategic investment. It boosts production efficiency, improves quality, and increases flexibility across industries.

CNC Plasma Cutting – Flexibility and Power

Among sheet metal cutting technologies, CNC plasma cutting remains highly popular—especially where thick materials must be processed quickly and efficiently. While not as precise as laser cutting, plasma compensates with cutting force and flexibility.

How Does Plasma Cutting Work?

The technology uses ionized gas—plasma—to create an electric arc that melts the metal. CNC plasma machines precisely control movement and cutting parameters, ensuring repeatable results.

Applications of Plasma Cutting

CNC plasma cutting is particularly useful for thicker steel, aluminum, and stainless elements in industries such as construction, agriculture, and industrial machinery manufacturing.

Advantages

-

Strong cutting capability—handles thick sheets

-

High cutting speed

-

Lower investment cost compared to laser

-

Works reliably even in harsh workshop conditions

Limitations

-

Lower precision than laser

-

Wider kerf and greater heat-affected zone

-

Slag that may require removal

When Choose CNC Plasma Cutting?

It is an excellent choice for companies processing thick sheets that need an efficient solution without investing in costly laser systems.

CNC Press Brakes and Their Role in Processing

Although this article focuses on sheet metal cutting, bending is the natural next step—performed by CNC press brakes.

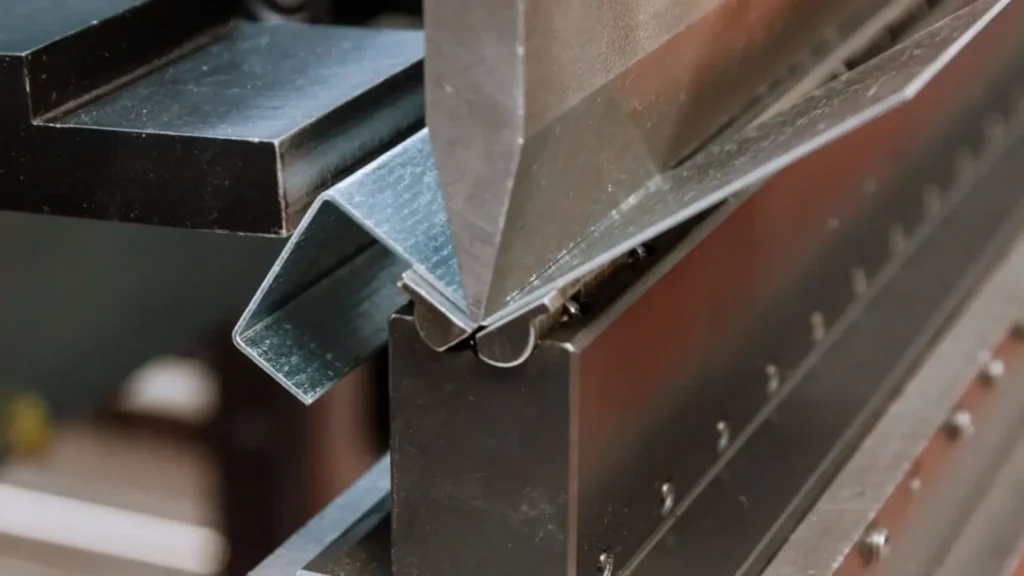

What Is a CNC Press Brake?

A CNC press brake is an advanced machine for accurately bending sheet metal at programmed angles. Numerical control ensures repeatability and eliminates operator-related errors.

Importance in Production

After fiber laser or plasma cutting, bending is often the next operation. Integrating these processes shortens lead times and reduces manual handling.

Key Benefits

-

High bending precision

-

Full automation with loaders/unloaders

-

Offline programming from CAD/CAM

-

Wide material and thickness range

CNC press brakes increasingly cooperate with industrial robots, pushing production into the Industry 4.0 era.

Smart Systems and Industry 4.0

Modern metalworking is no longer only about cutting and bending—it’s about data, automation, integration, and real-time analytics.

Integration of Machines and Software

CNC sheet metal cutting machines—fiber lasers, plasma cutters, press brakes—can now be integrated with CAD/CAM, MES, and ERP systems. Operators manage the entire process from one interface.

Automation in Sheet Metal Processing

Companies increasingly implement automation, including:

-

automated loading/unloading

-

sheet metal storage towers integrated with machines

-

collaborative robots for bending and sorting

-

palletizing systems for finished parts

Monitoring and Predictive Maintenance

Modern machines monitor tool wear, working time, material usage, and errors. Data helps optimize processes and predict maintenance needs before downtime occurs.

Sheet Metal Industry Trends for 2025

Upcoming years will be dominated by AI-based solutions, machine learning, and cloud analytics—further enhancing quality and reducing costs.

The Future of Sheet Metal Cutting Technologies

Technological progress in metalworking is accelerating. Innovations that once seemed futuristic are now becoming everyday tools.

Key Trends

Artificial Intelligence & Machine Learning

AI-powered CNC cutting systems optimize parameters in real time.

Hybrid Cutting Systems

Combining laser, plasma, or waterjet technologies for challenging materials.

Industry 5.0 – Human & Machine Collaboration

AR-based operator support, digital twins, and voice interfaces.

Innovations in Practice – A Step Toward the Future

Innovations in sheet metal cutting are already reshaping efficiency, quality, and competitiveness. From fiber lasers to CNC plasma cutting to automated sheet metal processing—each technology offers real benefits.

If you would like guidance in choosing the right cutting technology or want to learn more about modern equipment, feel free to contact our team. We will help you select a solution tailored to your production needs.