Welding delicate materials is a challenge that requires precision, experience, and modern technology. With the growing demand for welding delicate materials in the electronics, automotive, and medical industries, laser welders are increasingly becoming the preferred solution, offering quality and process reliability.

In this article, we explain why laser welding is becoming the leading method for working with thin sheets and demanding components. We present the operating principles of a CNC laser welder, its advantages, applications, and a comparison with traditional welding methods.

Why Do Delicate Materials Require Special Welding Methods?

For components made of thin sheets, lightweight alloys, or non-ferrous metals, standard welding techniques often prove insufficient. Welding delicate materials carries the risk of damaging them, and therefore requires technology that ensures maximum control over the process and precise parameter adjustment.

What do we mean by “delicate” materials?

This category includes, among others:

-

thin-walled stainless steel components,

-

thin aluminium sheets,

-

micro-components made of copper or titanium alloys.

These materials are sensitive to excessive heat, which can easily cause burn-through, distortion, or even melting during welding.

Problems in traditional welding

Using methods like MIG, TIG, or electrode welding on such materials can lead to:

-

local overheating and creation of heat-affected zones (HAZ),

-

geometric distortion,

-

deterioration of the material structure near the weld,

-

the need for additional finishing processes.

The need for precise technology

For these reasons, interest in precision laser welding is growing. It minimizes thermal influence on the surrounding area and enables clean, aesthetic joints — even in very thin materials.

How Does a Laser Welder Work and Why Is It Ideal for Thin Sheets?

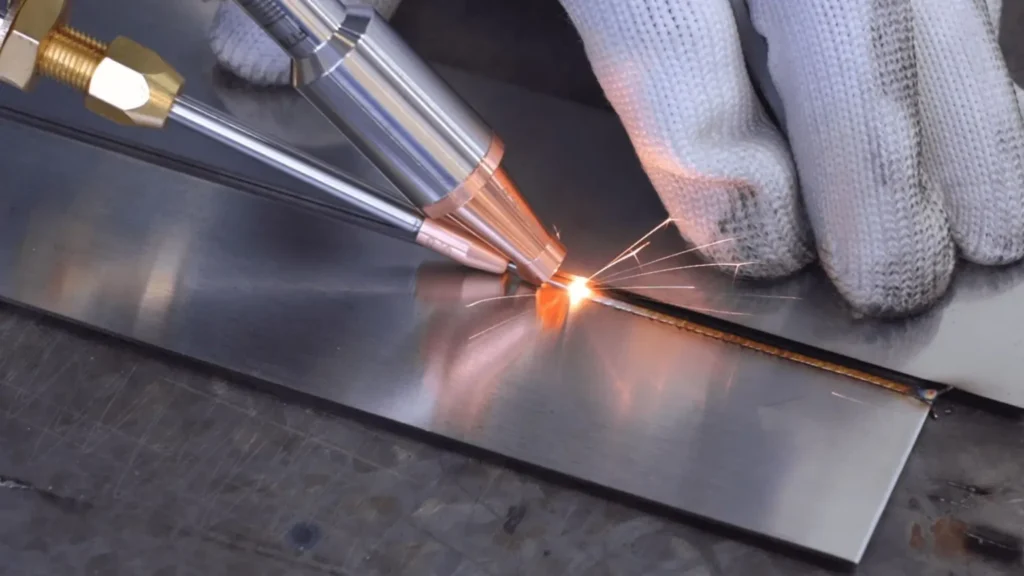

A laser welder for thin sheets uses a concentrated laser beam to join metal components permanently. Thanks to its extremely narrow working zone and precise control over parameters, it is ideal for materials sensitive to heat and deformation.

Operating principle of a laser welder

Laser welding focuses a highly energetic beam of light on a small area of the material, melting it quickly and forming a weld. Compared to traditional methods, laser welding technologies offer:

-

a very small heat-affected zone (HAZ),

-

minimal heating of the surrounding material,

-

no need for filler material (although it can be used).

Why is this ideal for delicate sheets?

Thanks to its precision, a CNC laser welder allows:

-

preservation of the material’s original properties near the weld,

-

reduction or complete elimination of thermal deformation,

-

welding even very thin sheets without burn-through,

-

perfect repeatability — especially important in series production.

An additional advantage: full automation

Modern laser welders operate in fully automated cycles, enabling integration with production lines, industrial robots, and quality control systems. This increases efficiency and eliminates the risk of human error.

Key Advantages of Laser Welding in Processing Delicate Materials

Precision laser welding is not only a modern technology — it directly solves problems that arise when working with thin and sensitive materials. It enables very high-quality welds without damaging the component.

The most important benefits:

Minimal thermal impact

Laser welding features a very small heat-affected zone, meaning the surrounding material does not deform or overheat. This is essential in thin-metal welding, where any excessive heat can cause distortion.

No deformation and perfect geometry

Thanks to precise control over beam parameters, it is possible to weld thin sheets without deformation. The components retain their original shape, eliminating the need for corrections or straightening.

Aesthetic and clean welds

A laser welder for thin sheets creates extremely narrow and uniform welds, often requiring no additional grinding or cleaning — crucial for industries where appearance is as important as durability.

Speed and repeatability

Laser welding can be fully automated, ensuring consistent quality and high production speed — ideal for companies focused on efficiency and precision.

Possibility of welding without filler material

In many cases, laser welding does not require wire or rod filler, leading to lower material consumption, reduced costs, and a cleaner process.

Practical Applications – Where Does Laser Welding Perform Best?

Laser welding of delicate materials is increasingly used in industries where precision, weld aesthetics, and minimal thermal influence are essential. Thanks to its versatility and reliability, laser joining has become the technology of choice for many demanding production environments.

Industries that most frequently use laser welders:

Medical industry

Production of implants, surgical instruments, and diagnostic devices requires perfect welds free of contamination and deformation. Thin-sheet welding (e.g., stainless steel) must comply with the highest standards of cleanliness and accuracy.

Electronics and micromechanics

Miniature components made from thin copper, nickel, or aluminium sheets require extreme precision and minimal interference with internal structures.

Automotive and aerospace industries

Laser welding of aluminium and delicate body components ensures strong joints without adding weight or risking corrosion or structural weakening.

Production of housings and sheet-metal structures

This includes housings for machines, electronic devices, switchgear, control cabinets, and aesthetic exterior panels. A laser welder for thin sheets produces smooth, visually perfect welds visible to the end user.

Laser Welder vs. Other Methods – Comparison

Although laser welding is not the only technology used for joining thin and sensitive materials, it is often the most effective. How does it compare with MIG, TIG, or micro-plasma welding?

TIG Welding

-

Often chosen for thin-sheet welding but requires high operator skill.

-

Larger heat-affected zone → potential distortion.

-

Slower and more demanding than laser welding.

MIG Welding

-

Better for thicker materials rather than delicate sheets.

-

Less precise welds, often requiring finishing.

-

Higher filler-material consumption.

Micro-plasma welding

-

Very precise but costly and less universal.

-

Limited in speed and automation.

| Criterion | Laser Welding | TIG | MIG | Micro-plasma |

| Weld precision | Very high | Medium | Low | High |

| Material distortion | Minimal | Moderate | Large | Low |

| Automation capability | High | Limited | Limited | Limited |

| Aesthetics & cleanliness of weld | Very good | Good | Poor | Good |

| Operating costs | Medium | Low | Medium | High |

Is It Worth Investing in Laser Technology?

Although laser welding may seem more expensive upfront, in practice it provides significant savings and competitive advantages, especially for companies handling thin and delicate materials.

A laser welder is a good choice when:

-

weld precision and minimal deformation are essential,

-

production is serial and requires automation and repeatability,

-

the industry demands process cleanliness — medicine, electronics, aerospace,

-

you want to reduce or eliminate the need for post-processing.

Long-term benefits:

-

lower labour costs through automation,

-

reduced or no filler-material consumption,

-

shorter production cycles → higher throughput,

-

increased product quality → improved reputation and customer loyalty.

Integration with modern production

CNC laser welders easily integrate with production lines, robots, and CAD/CAM systems — ideal for companies implementing Industry 4.0 automation strategies.

Innovative Welding in Practice – A Step Toward the Future

Welding delicate materials requires technology that provides precision, reliability, and full control. This is exactly what a laser welder for thin sheets offers — a solution rapidly becoming standard in modern production.

Regardless of whether you operate in the medical, electronics, automotive, or industrial sector, precision laser welding can significantly enhance product quality and streamline manufacturing processes.

If you are considering implementing this technology or want to discuss selecting the right system — contact us. We will help you choose equipment tailored to your production needs and prepare a customized offer.