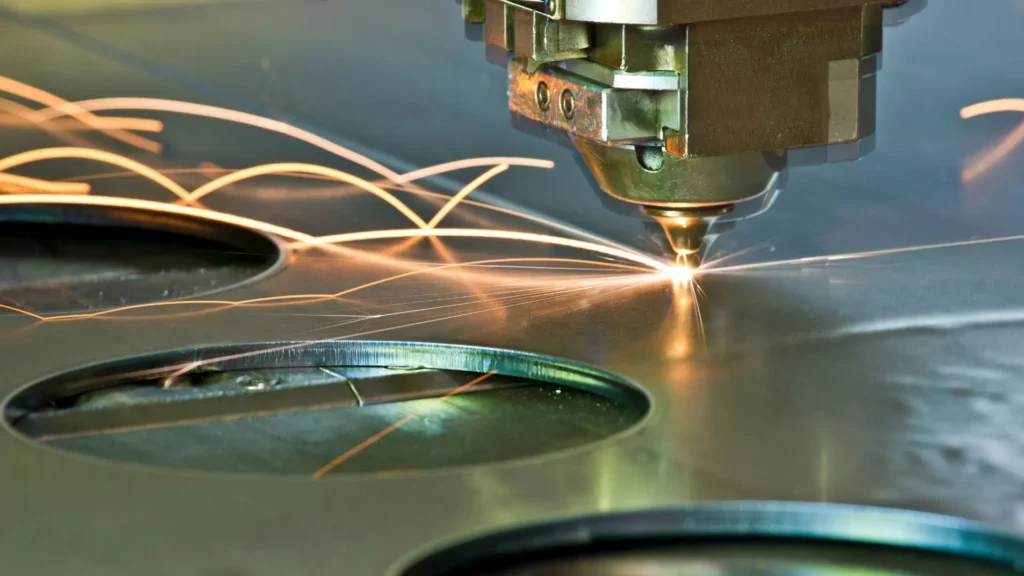

Applications of plasma cutting machines today span nearly every sector of industry – from construction and automotive to functional art. Thanks to their versatility, speed, and efficiency, plasma cutting applications continue to expand, responding to the growing demands of both precision and mass production.

In this article, we present 10 specific examples where CNC plasma cutting delivers tangible benefits – both when working with thick steel plates and decorative aluminum details. You will learn how a plasma cutting machine supports modern production lines and small workshops in creating components faster, more cost-effectively, and with excellent quality.

Construction and Structural Industry

In the construction sector, a metal plasma cutting machine plays a key role in preparing structural components. Thanks to its versatility and high power, it enables plasma cutting of thick materials, such as steel beams, hollow sections, and heavy-gauge plates.

Main applications:

-

Cutting load-bearing elements for steel halls, warehouses, and support structures

-

Production of components for roof and wall frameworks

-

Cutting foundation plates and steel connectors

Compared to mechanical cutting methods, CNC plasma cutting shortens material preparation time and provides higher precision with minimal tool wear.

Why plasma?

-

No need for material pre-treatment

-

Ability to work with large-format plates and profiles

-

High cutting speed, even at thicknesses above 20 mm

Thanks to these features, plasma cutting machine applications in construction are now a standard – both in large infrastructure projects and in steel structure prefabrication.

Machinery and Equipment Manufacturing

In the industrial machinery and specialized equipment sector, plasma cutting machines in industry play a major role – especially where material flexibility and rapid response to design changes are essential.

Typical applications:

-

Cutting machine frames, base structures, and brackets

-

Creating covers, holders, and housings from various types of steel

-

Preparing components for welding and further processing

CNC plasma cutting machines enable fast production of parts with diverse shapes – both in prototyping and series production. This makes them ideal for companies manufacturing custom machines.

What does the manufacturer gain?

-

Rapid implementation of design changes

-

Ability to work with materials of varying thicknesses

-

High edge quality and reduced finishing time

In this industry, plasma cutting applications translate directly into shorter production times and increased competitiveness.

Agriculture and Heavy Industry

In agriculture and heavy industry, CNC plasma cutting is widely used in the production and repair of large, durable components. A metal plasma cutting machine easily handles thick structural steel, making it ideal for plants manufacturing or servicing agricultural, construction, and mining machinery.

Most common applications:

-

Production of frames, suspensions, and chassis parts for agricultural machines

-

Cutting adapters, connectors, and brackets from structural steel

-

Manufacturing guards, arm elements, excavator buckets, and loaders

Plasma cutting of thick materials is indispensable here – no other technology offers such speed and efficiency when cutting steel sheets 20–50 mm thick.

Why a plasma cutting machine?

-

Ability to operate in harsh production environments

-

Handling of large, heavy components with wide tolerance ranges

-

Easy integration with welding and further processing

In practice, plasma applications in production of agricultural and industrial machinery are now standard – especially where reliability and durability matter most.

Automotive Industry and Tuning

For many workshops involved in vehicle tuning and modification, a plasma cutting machine in the automotive industry is an indispensable tool. It enables precise plasma cutting of sheet metal and fast, flexible customization of components for individual projects.

Automotive applications:

-

Creating and modifying exhaust systems

-

Cutting body panels, mounts, brackets, and custom components

-

Producing parts for roll cages, underbody protection, and off-road tuning

Thanks to plasma-based metal cutting technologies, even small workshops can handle custom orders without investing in expensive molds or dies.

Why plasma works in tuning:

-

Fast prototyping and custom-dimension cutting

-

Ability to work with various sheet thicknesses – from thin panels to thick frame elements

-

Clean edges and good weld quality, crucial for visible modifications

In practice, plasma cutting machine applications in automotive work provide enormous design freedom while increasing precision and repeatability, even in small-batch production.

Fence, Gate, and Balustrade Manufacturing

In the fencing and metal construction industry, a metal plasma cutting machine enables fast and precise production of both standard and decorative elements. It is an ideal solution for companies using CNC plasma cutting to manufacture gates, wickets, balustrades, and decorative panels.

Typical applications:

-

Cutting decorative patterns in steel and aluminum sheets

-

Creating infill panels for balcony balustrades

-

Producing decorative spans, plaques, initials, and personalized motifs

Thanks to high cutting speed and the ability to work with thin sheets, plasma cutting machine applications across industries also include aesthetic details where precision and edge quality are essential.

Why plasma?

-

Design freedom – cutting directly from CAD/DXF files

-

No need for additional processing – clean, even lines

-

Single-piece or series production – without compromise

Companies offering custom gates and balustrades value this technology for its flexibility, repeatability, and final result that often goes straight to the customer without further finishing.

Shipbuilding and Offshore Industry

In shipbuilding and offshore sectors, plasma cutting of thick materials is an everyday necessity. Working with plates 30–60 mm thick, often in harsh environmental conditions, requires reliable, high-performance technology. Here, plasma cutting machines in heavy industry have no equal.

Main applications:

-

Cutting hull plating and platform components

-

Producing frames, bulkheads, decks, and load-bearing elements

-

Preparing structural steel sheets for welding and bending

CNC plasma cutting machines in shipyards often operate in multi-shift mode, handling massive material formats with millimeter precision – something that until recently was the domain of oxy-fuel cutting.

Why plasma in shipbuilding?

-

Very high efficiency when cutting thick steel

-

Ability to process irregular or contaminated materials

-

Automation and integration with CAD/CAM systems

In practice, plasma cutting machine applications in shipyards mean not only higher productivity, but also better prefab quality – resulting in faster assembly and greater reliability of finished vessels.

Pressure Vessels and Tank Manufacturing

In the production of pressure vessels, boilers, silos, and heat exchangers, metal cutting technologies must combine precision with reliability. Every millimeter counts – from tightness to component fit. That is why a steel plasma cutting machine has become standard in such applications.

Typical applications:

-

Cutting dished heads, flanges, nozzles, and process openings

-

Cutting shell elements and jackets from thick plates

-

Preparing precise edges for circumferential welding

In this industry, plasma applications in production ensure repeatability and perfect component fit, directly affecting tightness and safety.

What does plasma deliver?

-

No burrs or distortion – ready for welding

-

Ability to work with large-diameter, thick plates

-

Accurate holes for bolts, nozzles, sensors, and fittings

As a result, CNC plasma cutting accelerates production and reduces error risk – critical in pressure vessel manufacturing.

Energy Sector and Industrial Installations

In energy and industrial installation sectors, plasma applications in production play a major role – especially in creating support structures, ducts, cable trays, and pressure pipelines. CNC plasma cutting allows fast adaptation of components to complex technical systems, where accuracy and reliability are key.

Most common applications:

-

Cutting openings and channels in steel enclosures for switchgear and industrial cabinets

-

Producing frames, racks, and supports for cable trays and ventilation systems

-

Preparing structures for solar installations, HVAC systems, and piping networks

A plasma cutting machine in the installation industry is an ideal tool for rapid prototyping, component customization, and series production with consistent quality.

Why plasma?

-

Material versatility – carbon steel, stainless steel, aluminum

-

Ability to cut complex shapes tailored to project requirements

-

Flexibility for one-off and large-scale production

Installation and contracting companies increasingly rely on in-house or subcontracted CNC plasma cutting machines to shorten project timelines and reduce on-site processing.

Advertising and Industrial Signage

The advertising industry is increasingly turning to precise plasma sheet metal cutting, especially for outdoor signage, lightboxes, panels, and metal logos. A plasma cutting machine in the advertising industry enables fast, clean, and repeatable execution of even the most complex graphic designs.

Advertising applications:

-

Cutting 3D letters from aluminum and stainless steel

-

Creating customized signs and company logos

-

Producing lightboxes and branding elements from sheet metal

Thanks to CAD integration, CNC plasma cutting transfers graphic designs directly onto material – without molds, routers, or dies.

Why plasma?

-

High accuracy and detail reproduction

-

Cutting thin and medium-thickness materials without distortion

-

Ideal for one-off and small-batch projects

In this industry, plasma cutting machine applications directly affect the visual quality of finished products – often the first point of contact between a brand and its customer.

Artistic Workshops and Craftsmanship

More and more small workshops and art studios are using plasma cutting machines as creative tools. Today, plasma cutting machine applications across industries include not only heavy manufacturing, but also craftsmanship and functional art.

What do artisans and artists create?

-

Garden decorations, façade panels, and metal art elements

-

Metal hooks, shelves, lamps, clocks, and loft-style furniture

-

Personalized signs, crests, plaques, and gift items

Thanks to CNC plasma cutting, workshops can quickly reproduce designs in metal – without sacrificing quality or time.

Why it works:

-

Design freedom – even the most complex patterns from graphic files

-

Ability to work with various materials: steel, aluminum, corten

-

Single-piece and short-run production – ideal for craftsmanship

For small studios seeking to stand out through quality and individuality, plasma applications in production offer a perfect blend of creativity and technological precision.

Plasma Cutting as a Universal Industrial Tool

As these examples show, plasma cutting machine applications span nearly every industry – from heavy manufacturing to artistic craftsmanship. It is a technology that combines precision, speed, and flexibility when working with various materials and formats.

Thanks to CNC plasma cutting, companies can significantly shorten production times, improve quality, and increase repeatability – without investing in complex molds or costly tooling. Whether you produce steel structures, advertising lightboxes, or decorative garden elements, a metal plasma cutting machine can become a key component of your production line.

Want to learn how to choose the right machine for your business needs?

Contact us – we will help you select a solution tailored to your industry.