Are you preparing to purchase a press brake? Not sure which tooling accessories to equip it with? In this article, we explain the types of clamps used on press brakes and what they are designed for.

Clamps as a Component of the Press Brake – What Is Their Function?

A press brake is a machine used for bending, most often sheet metal. It allows programmed bends to be created by clamping the workpiece between a properly selected punch and die.

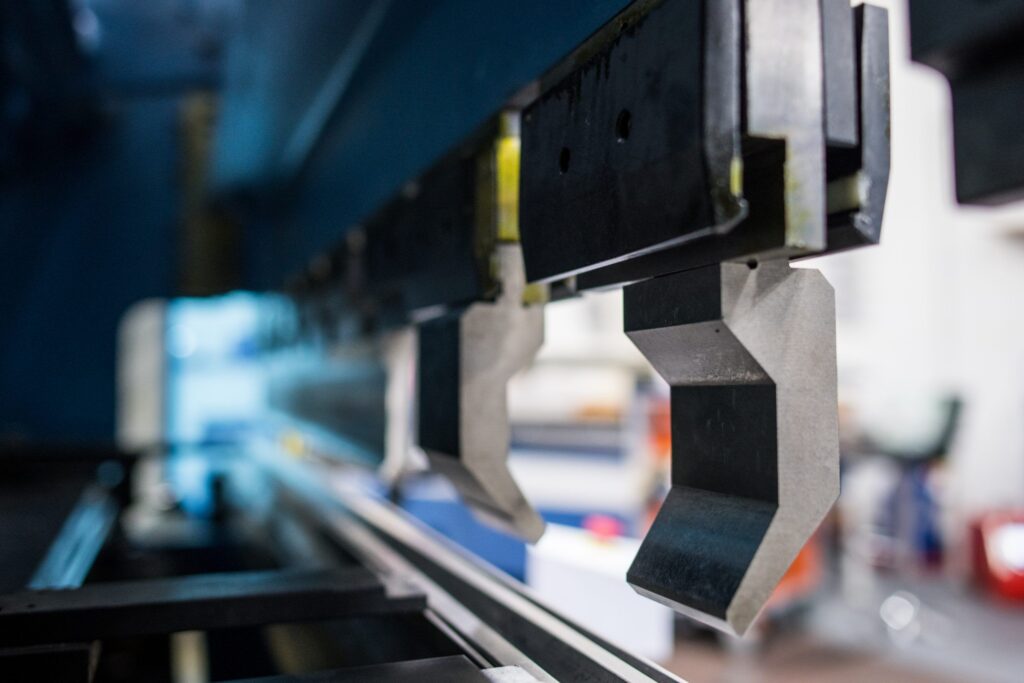

Clamps are used to mount the punch to the press brake. This component is responsible for keeping the punches aligned with the bending beam. Mounted directly to the beam, they absorb a significant portion of the load generated during the bending process. Due to these loads, not only functionality but also durability is crucial. Our fast-clamps allow for rapid tool changes according to the operator’s needs. Undoubtedly, fast tool change means not only time savings, but also greater precision and convenience in the punch clamping process.

Amada Promecam clamp – double-sided

What Types of Clamps Are Used on Press Brakes?

There are two types of clamps used on press brakes. They are primarily distinguished by the method and location of clamping, and above all by their design. If you are unsure which clamps to choose for your press brake, contact us. Our technicians will help clarify any doubts.

Press Brake Clamps – The Following Factors Influence the Choice:

-

press force and punch strength

-

frequency of upper tool changes

-

dimensions of the press brake working area

-

dimensions and weight of the punches

In press brakes, we distinguish two groups of clamps: permanently built-in or interchangeable.

Otinus machines are equipped with interchangeable clamps with Amada Promecam quick-clamping, for which tools can be purchased from the Polish company Plasmet. This is the result of growing demand for machines on the market and the attractive pricing of tools with this clamping system.

Permanently built-in clamps further speed up tool changes. Along with speed, however, comes a high price and limited versatility of such a solution. The leader in this system is the WILA New Standard Premium clamping system.

Single-Sided or Double-Sided? – Which Model Should You Choose?

Single-Sided Clamps

If you produce uncomplicated parts, in most cases single-sided clamps will be sufficient. This is the standard solution in our press brakes. They allow punches to be mounted from the front, toward the operator. With complex shapes, however, there is often a need to insert a significant portion of the part into the press brake working area. This is inconvenient and may cause additional difficulties or even make the part impossible to manufacture. What does this mean? The operator will have less control over dimensional accuracy due to the difficulty of bending narrow C- and U-shaped elements.

Double-Sided Clamps

With standard, single-sided clamps, most subsequent bends must be performed from the already bent sections of the workpiece. If you plan to provide bending services and value versatility, it is definitely worth equipping your press brake with double-sided clamps. Thanks to them, you can control the entire process while maintaining accuracy and efficiency. The use of double-sided clamps eliminates dimensional errors resulting from incorrect angles in previous bends. This solution enables a simpler and clearer quality control process and reduces frequent mistakes caused by operator oversight.

Double-sided clamp – allows punches to be mounted in two directions

Practical Examples of Using Double-Sided Clamps

In practice, as mentioned, double-sided clamps are used for bending C- and U-shaped parts or more complex geometries.

Below, I will present several images showing the practical application of these clamps on the Otinus PBO-2563-CNC OT-41 press brake.